Servicios de pozo, Registro y Cañoneo

Nuestra capacidad de mejora e innovación, así como nuestro conocimiento, han puesto al descubierto el verdadero potencial de los yacimientos en varias cuencas petroleras en todo el mundo.

Somos un proveedor internacional innovador de diversos servicios de pozos, incluidos los servicios con unidades de cable de registro y cañoneo, que permiten una comprensión completa del yacimiento. Nuestras soluciones brindan información vital de perforación y datos de pozos más precisos para evaluar mejor el potencial de producción y aumentar el retorno de la inversión.

Nuestra capacidad de mejora e innovación, así como nuestro conocimiento, han puesto al descubierto el verdadero potencial de los yacimientos en varias cuencas petroleras en todo el mundo desde 1966. Con nuestra gran trayectoria y capacidad para realizar tareas desafiantes, podemos producir una comprensión más detallada de los complejos subsuelos y maximizamos el valor del yacimiento a lo largo de su ciclo de vida completo.

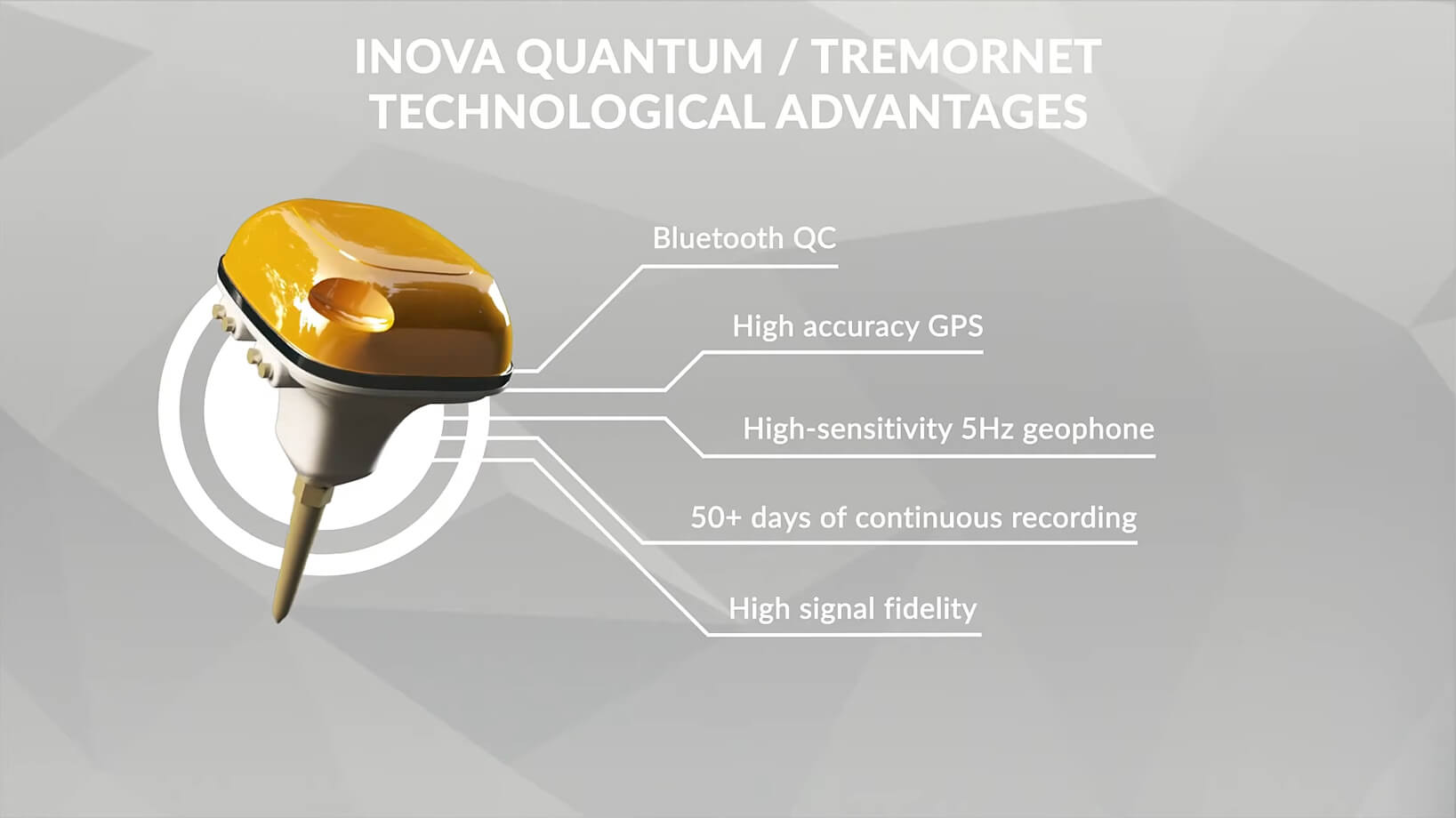

Nuestras soluciones innovadoras abordan con éxito una amplia gama de objetivos. La exploración de hidrocarburos y minerales, la industria minera, depósitos subterráneos, al igual que la energía geotérmica son algunos de los sectores en los que sobresalimos. GT también ofrece servicios especializados en pozos profundos y también en pozos someros de diámetro pequeño hidrogeológicos, geotécnicos y de geoingeniería.

Estamos orgullosos de nuestros logros en el análisis de los entornos de pozos más exigentes. Varios clientes, desde medianas empresas hasta las más grandes empresas de la industria, han confiado en nosotros. Permítanos ayudarlo a obtener una comprensión más completa de sus yacimientos y finalmente reducir los riesgos y costos de las operaciones de pozo. ¡Permítanos superar sus expectativas!

Nuestros servicios y soluciones para pozos

- Evaluación de Formación

- Evaluación de la formación detrás del revestimiento

- Servicios de registro de superficie / registro de lodo

- Servicios de cañoneo:

- Sistemas de cañoneo recuperables en huecos abiertos

- Sistemas de cañoneo a través de la tubería de producción

- Tapón y cañoneo de bombeo horizontal

- Servicios de estimulación con propelente

- Servicios de cierre y abandono de pozos sin taladro

- Operaciones de recuperación de tuberías

- Registro de producción

- Registro de integridad de pozos